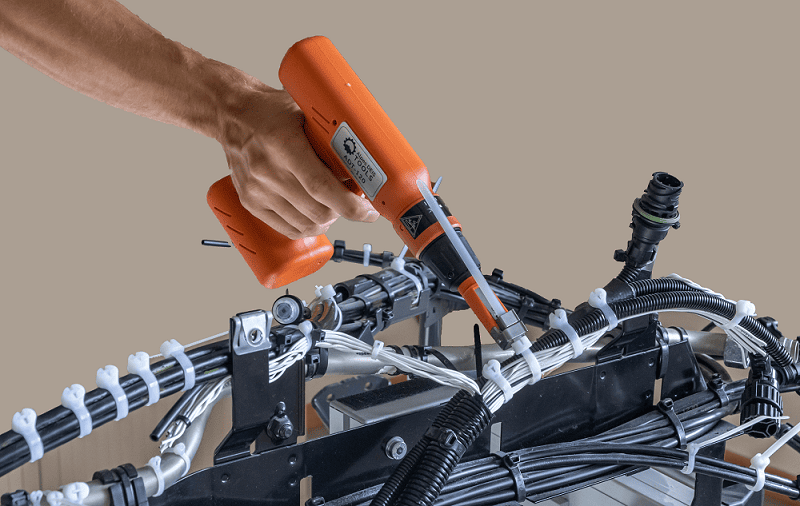

How to choose the right cable ties tightening tool?

What are these zip ties tightening tools used for?

Cable ties clamping tools are needed in industrial settings, from light to large quantities of zip ties used daily. They can ease the operation thanks to a force setting, a better cut and less strength needed by the operator. It can therefore be found in many different industries such as truck assembly, railway or aerospace production, medical equipment production or energy.

What tool to choose from?

When it comes to tightening plastic cable ties, you can find many different types of tool to help you with this repetitive tightening operation. Manual pliers are the most common, but you can also find pneumatic or electric tools. As you saw in one of our previous articles, each has its advantages and disadvantages. Here's a summary of each type.

| Types of tool | Characteristics |

|---|---|

Manual clamp |

|

Pneumatic clamp |

|

Automatic tool |

|

Battery power tool

|

|

What to look for to choose the adapted tightening tool?

Several areas should be looked at to confirm the need. Let’s look at a non-exhaustive list:

- Current organization: pneumatic network in the plant or focus on other kinds of equipment, fixed or moving station.

- Cable ties manufacturer recommendation: width of cable ties, the adapted force recommended, its composition and characteristics.

- Condition of the post: quantities tighten, low or high yield, large or limited resting time, rotation in the team.

- Operators condition: strength or capacities, passed medical conditions.

Specific cases in the application

4.8mm width, or in-between tools' range

Some tools range can either end or start at a cable tie width of 4.8mm. If you face this situation, it will then depend on the tension recommended and the type of harnesses used. Some tools may offer various tensions depending on the range of width offered. Smaller cable ties tend to have a smaller tension recommended whereas larger cable ties will require a larger force. You will also have to consider the type of harnesses as it may have an influence on the tension needed.

Support characteristics

Consider the support, types of harnesses used for your production. As we started to mention, different kinds of harnesses will require different tension and application. Indeed, a large cable tie may be use so may require a larger force, but if the harness is made of soft hoses, there is a risk of compression. On the other hand, using a low force may not fix the cables correctly and be too loose. Take into account that all cable ties with slightly loosen during the first 24 hours.

A few tips on how to spot a good tightening

- The cable ties should be able to turn on the spot but should not move along the cables.

- There is a maximum force that should not be exceeded – the elastic limit of the ties. If exceeded a deformation will occur and not possible to cut it.

- If estimating the forces available for each tool is not enough to ensure the quality of the tightening, a measurement certificate may be produced per head for a precise tension definition.

To sum up, what should you look for?

- Check the requirements of the plant and stations concerned.

- Check the width of your cable ties and the manufacturer's tension recommendation.

- Check the conditions of the post and operators.

- Define the type of tool best suited according to these values.

- To confirm or if several apply, validate with a demonstration or test if possible. Ask for a measurement certificate if necessary and if the brand is able to provide it.

Healthier and happier workforce

Healthier and happier workforce

Improved Quality and Process

Improved Quality and Process